In IoT Device Design, Size Matters

Our mission is to help businesses connect, protect, and derive more value from their assets. As a leading global innovator, developer, and supplier of IoT solutions, we drive continuous innovation to enable our partners to deploy confidently at scale worldwide.

In this article, Digital Matter CEO and Founder Ken Everett discusses key considerations in IoT device design, size and performance.

This article was originally published online at piplinepub.com and printed in Pipeline Magazine | Volume 17 | Issue 9

After a year hampered by COVID-19, Internet of Things (IoT) spending is rebounding, with double-digit growth expected in 2021, and a compound annual growth rate (CAGR) of 11.3 percent over the 2020-2024 period, according to analyst firm IDC. As awareness of the Internet of Things market grows, businesses of all sizes and in every industry are continuously thinking about ways they can incorporate IoT into their day-to-day activities to drive down cost and improve efficiencies.

According to a study by analyst firm ABI Research, asset tracking is one of the highest-growth segments in the IoT market. ABI expects 51 percent growth per year through 2024 as the industry moves from tracking only high-value goods into low-value, high-volume markets, which will quickly account for most shipment numbers.

As new business cases emerge for the IoT as device and connectivity costs continue to decrease, businesses are able to broaden the range of assets they track. This often leads to requests for some interesting devices, most of which need to be small. But does hardware size really matter in the IoT, and what are the trade-offs?

Technology is advancing rapidly, and building smaller devices is possible given some of the higher-density integrated circuits and smaller components available. However, there are some fundamental technical reasons why smaller is not necessarily better. There often needs to be a compromise between the size of the device and its performance, both in terms of battery life and radio frequency (RF) efficiency.

Battery Size

The goal of any battery-powered asset tracking device is to last for the useful life of the asset: deploy once and never have to change the batteries. The logistical cost of having to maintain and service batteries has been a barrier to broader adoption of many IoT devices.

Battery technology as it relates to IoT devices has not advanced much in recent years. The simple fact remains that if you reduce the size of your battery power source, the amount of energy to power your device decreases. This is fine for customers who start with a usage profile in mind and know exactly how much power their device needs to operate over a given period of time. However, what usually happens is when companies see success with small projects, they quickly want to update to more aggressive tracking parameters, which then require more energy usage. These low-power projects can quickly demand more power requirements.

Primary lithium cells are the most suitable for the majority of use cases, and common batteries include LiFeSO2 (for example, Energizer Ultimate Lithium) and LiSOCl2 (lithium thionyl chloride or “LTC”). These provide some of the highest energy densities and are able to deliver the peak currents needed during the transmission of data. Both of these chemistry types offer good temperature ranges, with the LTC batteries being the most suitable for harsh temperature environments such as heat, humidity, dust, and other conditions. Sticking to “off the shelf” primary cells when determining battery type means batteries are readily available for partners to purchase directly. The end customer can even buy replacement batteries themselves as needed from their local home improvement or department store.

Lithium coin cells (for example CR2032) are used in a number of small devices such as Bluetooth tags or beacons due to their small size. These coin cells have relatively low specifications for peak current (typically 30mA max) so cannot be used to power a cellular modem, or even peak LoRaWAN® or Sigfox transmissions.

Rechargeable battery packs are useful for scenarios where the device can be regularly plugged in and recharged. One example of this is in bike or scooter tracking—the equipment’s battery is generally charged overnight, and the asset is placed back on the street in the morning. However, in IoT asset location scenarios, most customers want to minimize the amount of interaction required with the device once it has been deployed. It must “just work” with a typical expected battery life of three to five years, or even longer. Think industrial applications where the IoT devices are in hard-to-reach locations, such as in the mining and oil and gas industries.

Advancements are being made in lowering the amount of energy needed to generate a location or sensor data for the asset and in the energy required to transmit that information up to a back-end system that can act on that information. Cloud-based location solving on our latest indoor/outdoor battery-powered asset tracking solution, the Yabby Edge, for example, saves power by moving the location processing workload from device to cloud. Lower energy needed means benefits including longer battery life, smaller batteries, and more frequent updates.

Antenna and PCB Size

To understand antenna and PCB size, some elements of physics should be summarized as they relate to RF signals. A dipole antenna has two radiating elements, with the optimal length of the radiators being inversely related to the frequency of the signal being transmitted (and received). The lower the frequency, the larger the radiating elements need to be to operate efficiently.

Embedded chip antennas, meanwhile, have a single radiator so the ground plane of the PCB becomes the second radiator. For signals below 1GHz, the length of the ground plane (PCB) should typically not be less than 100mm, otherwise, the efficiency will be reduced.

The antenna efficiency can be understood as the ratio of the power radiated by the antenna to the power output from the transmitter. Lower efficiency means lower range (the device might not be able to communicate properly). It also means the transmitter needs to use more power to get range—and it results in shorter battery life.

LPWAN networks like LoRaWAN and Sigfox operate in sub-1GHz bands, typically in 868MHz and 902-928MHz bands. Cellular LTE-M / NB-IoT networks also make common use of cellular bands below 1GHz and even as low as 698MHz. Almost all of these networks require some form of RF testing and compliance or certification testing to ensure that the device operates efficiently on the network.

GPS Performance

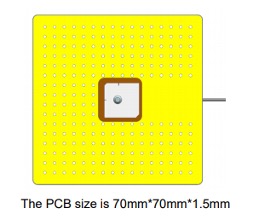

The GPS (GNSS) on IoT devices also has an antenna and, even though it is only used to receive signals from the satellites, the ability of the antenna to efficiently receive the strongest signal possible can make a massive difference in device performance. It is an antenna just like any other. An example is a typical GPS (GNSS) ceramic patch antenna of 18mm x 18mm size. It sounds great—nice and small. But the recommended ground plane size that it should be used with is 70mm x 70mm—hardly small at all.

|

| Figure 1: Antenna vs. Ground Plane Size |

The bottom line is that as the size of the ground plane is reduced in the design, it is harder to keep the RF performance of the device working optimally. Depending on the type of device, there may be some options—for example, designing the antenna of a connected watch into the strap of the device.

Housing Size

Some battery-powered devices are designed to be housed in IP67-rated housings, meaning they are fully waterproof and dust-proof. These housings have a seal, typically made of silicon, that sits in a special channel in the housing to ensure the housing seals correctly. This needs to work effectively over the temperature range of the device. The rugged plastic housing and the space required for the seal adds to the overall size of the device.

An example of this is a “snap” housing that takes the exact same PCB inside it as the normal IP67-rated housing, but it does not have a seal—or the IP67 rating. The result is the smallest possible housing for devices in scenarios where waterproof housing is not required.

Size vs. Performance

As the IoT market grows, so too do the different applications and use cases that companies are demanding. The life of an IoT device is not only dependent on the battery type and size but also on the design used when building out the device and use case. In some industries, the trade-off of battery life vs. size is acceptable, and in others, performance is the most important factor.

Technology advances are making it easier to walk the fine line between size and performance. However, it is important to work with a hardware manufacturer that takes into consideration the customer’s very specific use cases when creating devices. Many will have a range of device sizes that are designed to cater to a variety of use cases. Those that take into consideration battery size, antenna and PCB size, GPS performance, and housing size in their designs are the ones to watch.

Related News

Let’s Get Started

Submit the form to get in touch with a Digital Matter representative from your region.

Contact UsSubscribe

Get helpful content delivered straight to your inbox.

Let’s Get Started

Submit the form below to get in touch with a Digital Matter representative from your region.

Looking for support? Check out our knowledge base.

Information on becoming a Digital Matter Partner.

Information on pricing, availability, and proof of concept.

Guidance on selecting the right products for your application.